Get Rid of Odors in Your Home or Business

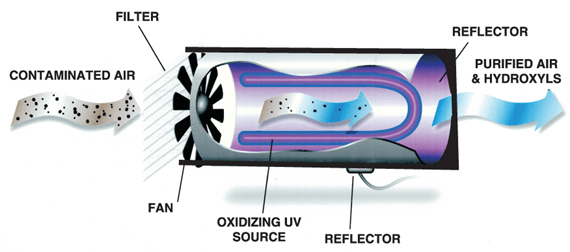

Smoke, pet urine, cooking oils, paints and fuel are just some of the odors that can stay trapped and impact your indoor air quality. Pure Air Environmental has successfully removed unpleasant odors in many homes and businesses. We use the latest hydroxyl generation technology, which replicates a natural cleaning process and allows homes and businesses to be occupied and operated normally during the cleaning cycle.

With our wide range of products and technology, we can eliminate odor at the molecular level. We don’t mask or filter smells for a few days, we completely eliminate them to keep your indoor air pure and clean. We also offer and recommend Puradigm air and surface purification systems to continuously decontaminate and keep odors and germs away. At Pure Air Environmental, every breath matters.

Are you dealing with unpleasant odors in your Indianapolis home or business? It's time to get rid of those lingering smells with professional odor removal services from Pure Air Environmental. Our experienced team specializes in odor elimination, using advanced techniques and high-quality products to ensure a fresh and clean environment. Whether it's pet odors, smoke smells, or any other unwanted scents, we have the expertise to tackle them all. Don't let odors affect your comfort and well-being. Trust our reliable odor removal services from Indianapolis to Anderson and restore freshness to your space. Contact Pure Air Environmental today and say goodbye to unwanted odors for good.

Odorox® Technology Benefits

Hydroxyls are often referred to as the “detergent” of the atmosphere, playing a critical run in cleaning the earth’s atmosphere.

In addition to being safe and effective, the hydroxyls will pull the odor out of the building structure and personal contents. Air circulation is the key component of a successful remediation. Anywhere air can travel the hydroxyls will neutralize the unpleasant odor to ensure it does not return. It is vital to refrain from painting prior to deploying the hydroxyl technology. The process will still work it just takes much longer to pull the odor molecules thru the latex or oil encapsulation.

The process allows buildings to be fully occupied during the remediation process. The only downside to occupied space is the noise factor during the remediation. Large air movers are used in conjunction with the generator to move air throughout the property. The air movers tend to be loud when used in multiple quantities.

Safe, effective and much cheaper than interior painting and replacing carpets and pads.

Odorox® Tackles Any Size Job

Odorox technology is widely viewed in the remediation industry as the leader in hydroxyl generation. The Boss XL3 units are routinely deployed to fight large spread forest fires each season in California and other western states. The Boss XL3 is also a "go to" standard for insurance industry remediation of major fire losses. Needless to say, the Boss XL3 can handle smoke odor from the most severe situations in homes and businesses to small scale jobs such as individual rooms or vehicle interiors.

The length of a remediation depends on several factors such as the type and severity of the odor, structure layout and total cubic volume, and number of machines needed. Most jobs take 3-7 days for the hydroxyls to permanently remove the odor. Large scale remediations or severe odors such as cigar smoke will likely be on the longer end of the cycle time. Smaller scale projects such as removing smoke from a vehicle interior typically resolve within 48-72 hours.

Get a Quote

By submitting, you authorize PureAir to reach out via phone, email, or text for explicit information about project needs. We will never share your personal information with 3rd parties for marketing purposes or spam you. You can opt out at any time. Message/data rates apply. Consent is not a condition of purchase. Terms and Conditions | Privacy Policy

What Our Customers Say

Find out what you're breathing?

Call us now.

Achieve a germ-free environment and prevent the spread of contaminants in your home, school, or business. Experience a significant reduction in viruses, bacteria, mold spores, radon gas, and unpleasant odors.